Energy & Utilities

Trimax has extensive expertise within the Energy and Utilities industry. Through our adaptability and innovative solutions, our team can help you accomplish even your most complex challenges.

Control Systems and Site Visibility

In an industry comprised of varying methods of collection and distribution, a dependable control system is vital. Trimax provides power generators and utilities with improved control and production capacity, as well as consistent and reliable reporting. Our custom programming and control strategy implementation allows for remote control of your system and increased efficiency.

Experience

Trimax has worked with wind turbine producers and installers to provide custom programming to remotely control the yaw and pitch of various turbines for increased efficiency. Our history with hydroelectric power ranges from program tuning for individual turbines to control strategy implementation for the entire Morris Dam project.

Trimax was responsible for all of the controls and systems integration for the Orange County cogeneration facility, which powers most of downtown Santa Ana, including critical sites like the courthouse and jail. These sites required a zero downtime solution: the cogeneration facility is completely independent of the normal power grid and must provide power at all times.

Trimax also has a longstanding partnership with Southern California Edison, in addition to other utilities, providing fabrication and testing on relay racks and MEER buildings for substations throughout Southern California. We are proud to be a Southern California Edison zero-defect partner.

Turn-Key Solutions

Trust Trimax to provide turn-key systems integration, programming, custom fabrication, and commissioning services for your projects. With experience in everything from panel and relay rack fabrication, to FAT testing and field service and startup, to extended maintenance, Trimax can help you achieve your project goals.

- Project planning

- System engineering

- SCADA/HMI

- Programming

- Fabrication of custom panels

- Integration and fabrication of relay racks and MEER buildings

- FAT and FTO testing

- Field service and start-up services

- Preventative maintenance and on-call emergency services

SCADA/HMI & Control Systems

Whatever stage your project is in, we can assist in its development. Trimax engineers have experience developing SCADA master plans for entire plants as well as planning control strategies for specific projects or connected systems. We use cutting-edge industry technology to deliver SCADA/HMI applications to your mobile devices, provide instant alarm notifications, and supply remote access for immediate response to systems in need of attention.

- Control strategy and process control development

- SCADA master plan development

- Modifications or conversions of old programs to newer versions or platforms

- Remote access and alarm notification

- Mobile SCADA applications

- Commissioning and functional testing

- Historical databases and reporting

Start-Up & Commissioning

Trimax deploys seasoned field service professionals to your project locations to ensure that systems are installed correctly and on schedule.

- System commissioning and functional testing

- Instrument maintenance and calibration

- System upgrades and optimization

- Certified variable frequency drive (VFD) startup

- Reporting

- Preventative maintenance

- Rapid-response service

- Maintenance and service available on contract or by incident

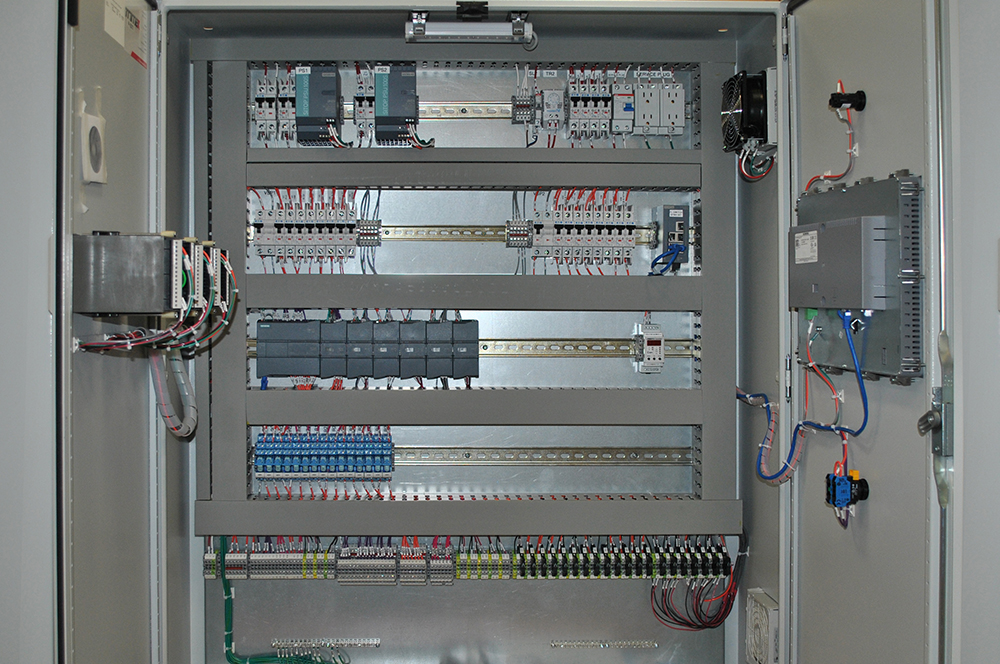

Custom Fabrication

Every project is unique. Trimax’s UL508a, 698a/b panel shop can assemble and wire any size and quantity of control and instrumentation panels with unsurpassed quality and performance. We fabricate quality terminals and control panels for the systems you need, designed to your exact specifications.

- Low and medium voltage panels

- Variable frequency drive (VFD) enclosures

- PLC and HMI control panels

- SCADA communication panels

- Remote input/output (RIO) panels

- Lighting panels

- Pump panels

- Substation relay racks and control buildings

- Custom enclosures and control panels ranging from explosion-proof push button stations to large-scale analyzers and sample panels

Maintenance

Our maintenance teams can provide monthly and annual maintenance or on-call needs, as well as predictive maintenance.

- Calibration of instruments and field devices

- Preventative maintenance

- System optimization and software upgrades

- Programming changes

- HMI screen additions

- Historical data logging

- Comprehensive customer-directed service

- Operator training